Rail Transport

Approved in aviation - ready for rail.

We bring our know-how and experience on composite solutions to the transportation industry.

Our well-established transportation products offer outstanding benefits designed specifically for the transportation market. Products that offer excellent reliability under the toughest of conditions and external influences leading to very long lifetimes. We can also optimize our lightweight constructions according to customer requirements to carry high loads adapted for every vehicle type.

Transportation in numbers

- 1000Trams equipped with EFWs composite products

- 15Cities and rural areas operate trams with advanced EFW products

- 50%of weight savings possible*

- 30+years of lifetime means a cost efficient and sustainable solution

* compared to common products and materials, such as plywood

Why use our composites?

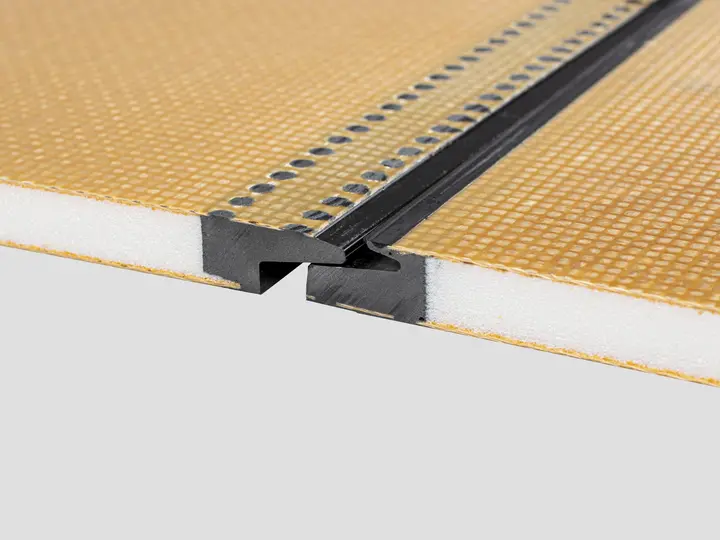

Our flooring supports your transportation needs

Manufacturing

From flat panels to 3D parts and from single panels to complex systems using various manufacturing options

Customization

Optimized lightweight construction according to customer requirements to carry high loads adapted to every vehicle type

Weight

Lightweight ensures weight savings of up to 50%; Positive impact on CO2 footprint

Reliability

Proven top reliability under the toughest conditions; Free from degeneration under external influences

Characteristics

Outstanding thermal insulation, noise absorption and fire safety properties; Service life up to 32 years

Function integration

Customization by system integration: Heating systems, provisions for electrics, hydraulics, pneumatics and mechanical applications

Composites with outstanding features and opportunities