A320/A321P2F

The New Generation Narrowbody Freighter

A new generation born out of proven experience

We are turning the world's best-selling single-aisle passenger aircraft family into the world's best freighter in its class.

Our converted A321 and A320 passenger-to-freighter aircraft offer both the lowest fuel burn in this class, as well as a fully containerized upper and lower deck for the first time in this freighter segment. We use highly reliable, state-of-the-art aircraft technology, with same type ratings for the Airbus family, and offer lower operational costs, and seamless cross-crew operation. Additionally, we offer freighter options according to your operational needs. For the A321/A320 this could be main deck cargo compartment access, several courier area layouts (e.g. for seats, galleys etc.) and more. Our A321P2F is uniquely positioned to replace ageing aircraft types in this class.

A321P2F benefits – the only freighter replacement in its class

- 9%less fuel burn per ton*

- 13.5%higher containerized capacity (14+10 full container positions)*

- 100%all major weight variants covered by our STC

- 99%random loadability – simply load and unload without balancing heavy/light loads*

* compared to Boeing 757

Product advantages

- Proven payload: Up to 28 tons (62,000 lbs)

- Best in class: 14 full size AAY main deck container positions + 10 AKH position in lower deck

- EFW’s conversion design (STC): covers all weight variants of A321-200

- Random loading: Minimum ground staff involvement

- Optimization: Less operational constraints (fuel restrictions, parcel arrangement etc.) due to optimized weight distribution

- Safety: Reduced workload and safe flight operations

- OEM data: Airbus provides full OEM data support backed by a NTO (non-technical objections)

- Support: Holistic customer support

A320P2F benefits – the best freighter in its class

- 4%less fuel burn per ton*

- 18%higher containerized capacity*

- 50%larger opening surface of doors – all open outwards*

- 60%less Turn Around Time*

* compared to Boeing 737-800

Conversion process

Our conversion process follows four key steps including major modifications to the entire aircraft and its systems. Step-by-Step becoming a freighter.

De-installation phase

The passenger and cargo deck areas are completely emptied and removed. This process includes removing interior fittings such as seats with all flight entertainment equipment and cabling, side wall cladding, insulation and floor panels.

Structural phase

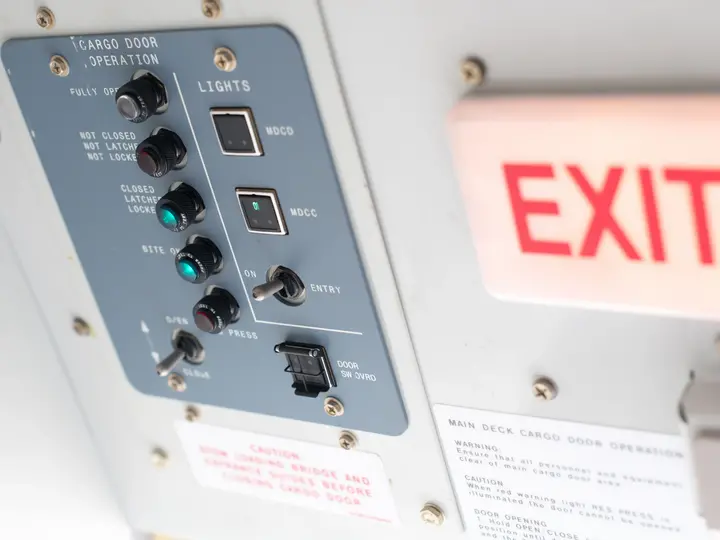

Work on the structure of the aircraft begins. The floor is rebuilt, stringers and frames are replaced or reinforced, the main cargo door is installed, the fuselage is reinforced, and windows and rear passenger doors are locked.

Re-installation phase

Once the structural changes have been made, we re-install items relevant to freighters. This includes computer systems and electrics, hydraulics, side panels and floors, and the crew rest compartment. At this stage we install our highly flexible Powered Cargo Loading System into the floor.

Test phase

The final stage sees all systems fully tested. We conduct hundreds of tests, including specific tests for freighters, covering everything from power, through the cargo loading system, to hydraulics and engines. After tests are completed the aircraft is released without the need for dedicated test flights.

Conversion features & modifications

Flexible cargo loading

Cargo loading system

Our Cargo Loading System, exclusive to A320/A321P2F single-aisle freighters, sets the bar in container volume. Featuring a unique capability to handle containers or pallets on both upper and lower decks, it optimizes space usage. This streamlined system guarantees swift handling, enhancing overall operational efficiency.

Aircraft data

| A320P2F* | A321P2F** | |

|---|---|---|

| fully containerized volume | 158m³ (5,603ft³) | 208m³ (7,348ft³) |

| payload data | up to 21 t (46,290lbs) | up to 28 t (61,750lbs) |

| range capability | up to 1,850 nm | up to 2,050 nm |

| maximum take-off weight (MTOW) | 77 t | 93,5 t |

| maximum landing weight (MLW) | 66.0 t | 77.8 t |

| maximum zero fuel weight (MZFW) | 62.5 t | 73.8 t |

* data refer to weight variant 012,** data refer to weight variant 011. EFW covers all A320 and A321 weight variants for conversion.

Further services

Maintenance, Repair and Overhaul

Learn more about our MRO capabilites for Airbus and defence aircraft

Customer Support Service

Learn more about our worldwide-support for P2F aircraft conversions and 24/7 support for maintenance activities

Approvals & Certificates

Learn more about our company approvals and certified management systems